I reached the limit of tolerance with my pocket compact digital camera as I realized my images were lacking sharpness when light conditions were not ideal.

Most of my images are displayed on monitors (web use) and only occasionally I print the very best pictures of mine.

While all images look great when displayed small things don't look so good once they are enlarged.

Add, low light and the tiny lenses of most compact cameras suddenly look a bit fuzzy.

If you believe that the images you take on your smart phone are good enough, then don't need to read any further: you are wasting you time.

I want better results for my photographic efforts but I refuse to schlep a large camera with me.

Weight and bulk are always my concern (some say, personal too :-) but gone are the days of toting around a large heavy camera.

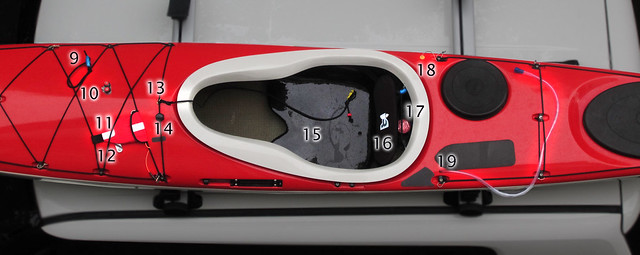

If the subjects that I want to photograph would be within reach of a short walk away from the car I would worry less, but when I take my cameras in a backpack and lug it around for days in the back country, or it has to fit inside my kayak on extended trips, then size does matter.

Olympus camera and lens compared to Nikon, similar focal length, same f/stop

For my second trip to Scandinavia I wanted to have a higher quality camera, one that allows me to apply my skills and one that would reward my creativity. My intention was no longer to simply record my trip, I wanted images I would be happy to hang on my wall.

The Micro Four Thirds system of cameras is the perfect compromise for me: images are sharp and the cameras have features than no other system has, size being one of the major ones.

I can afford to have a camera body and a couple of lenses with me and not really feel it in my backpack, something I could not do with a lot of DSLRs.

But where the Micro 4/3 system excels it also poses some problems with users with slightly bigger hands: the hand grips are often a bit small.

As I started to attach larger/heavier lenses on my Olympus cameras I felt that the grip was a bit diminutive and I had to clutch the camera too tightly.

I could use their Pro models but that would defeat the idea of compact and light: I just wanted a better grip, not a bigger camera.

same image sensor, different body, same image result

Commercially available add-on grips look too bulky (no need to have a base plate bolted to the bottom if one is not needed) and the glue-on aftermarket grips were not available for the camera I was using.

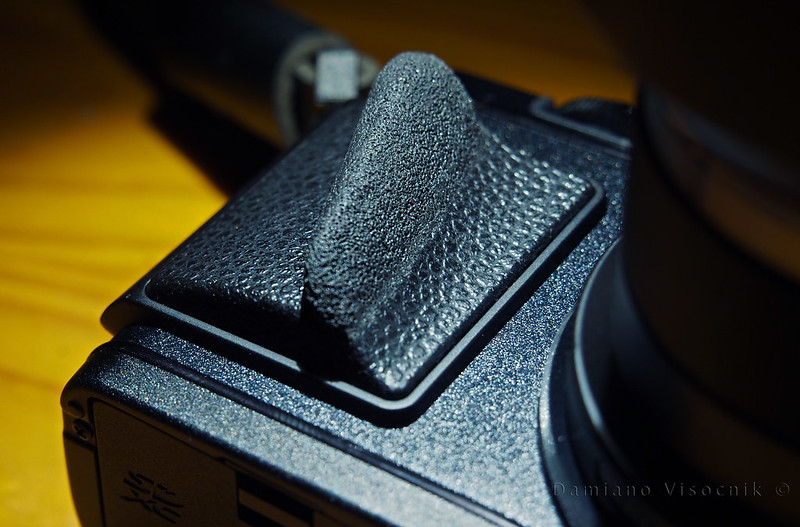

However those aftermarket grips looked really good and that prompted me to come up with my own DIY modified hand grips.

commercially available stick-on grip, here

I used Sugru, a silicon putty that feels like Plasticine but cures hard like rubber, sticks well and does not feel too slippery.

A small packet of Sugru contain enough material to shape a single grip if a large one is desired, or just enough for two smaller ones. Bright colors are available but I went with conservative black.

I have so far modified an Olympus E-PM2 (smallest of the M4/3 series) a couple of E-P5 and several E-M5.

Olympus E-PM2

Once the putty is kneaded and then firmly pressed onto the existing small protrusion where the fingers grip the camera, I shape the soft material with a small bladed knife to create a clean edge.

A moistened index finger keeps on shaping the putty until I am happy with the overall shape, then I run the back of the knife blade to create a perfectly uniform surface (not bumpy).

If the form of the grip is in its final shape I like to add some texture to enhance the surface and create more friction for my fingers.

Olympus E-P5

Here I use a combination of pins, pen ends (to create little circles) and an old toothbrush for finer texture.

I try to achieve a look that matches the existing camera finish but I simply will never be able to replicate the faux leather surface.

Before I let the camera rest to cure I check that there are no bits of stray silicon putty on the grip, where I don't want it.

While the cured silicon does become hard like rubber it is not impossible to remove it mechanically but one needs to scrape vigorously to get it off.

Olympus E-M5

I have seen some photographers push their fingers into the soft putty before it's cured to have an "imprint" look; I go for a more universal one where the grip is an extension of the original one and less fully-custom.

Olympus E-M5 and E-P5, modified grips

The grip on my Olympus cameras is now much more positive: my fingers don't have to clutch the body so tightly and the softer grip fatigues my hand much less when on longer photo shoots.

.

.