If however one considers a kayak just a tool and has little affinity with his/her craft then I don't think this skeg blade would excite them.

Just as some consider a car just a car and see no point in retrofitting it with performance accessories I am sure that to some a carbon-fibre skeg might seem an unnecessary replacement.

I don't care that much about my car but I will not say the same for my kayaks.

As all of my kayaks are rudder-less and incorporate an adjustable skeg for directional stability, I often wondered if the deployment of my skeg had as much effect on drag as when I would lower a rudder (it has been a few year since I have paddled an over-stern ruddered kayak).

In my Impex Kayak the skeg is a rather chunky HDPE blade (same material as the common kitchen chopping board); if I fully lower that skeg my kayak seem to slow down a bit and become a tad sluggish.

When Norbert Gancarz ( norbertga@o2.pl from Poland) offered me to test his latest creation, a carbon-fibre blade to retrofit the Valley skeg, I was keen to try it.

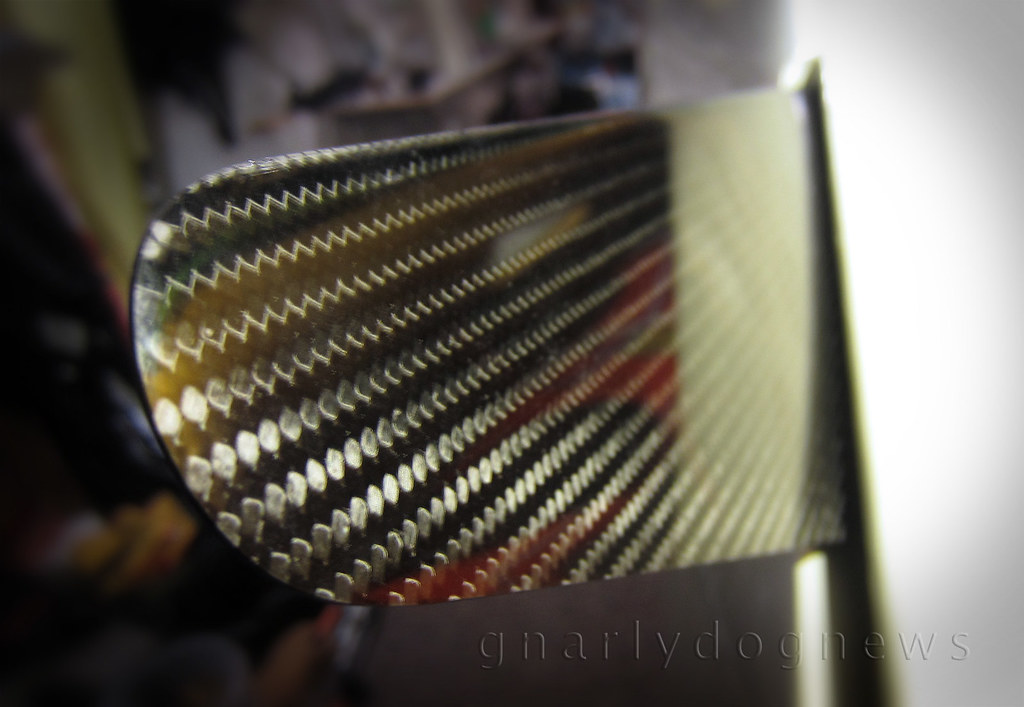

The skeg blade is of the exact outer shape as the VCP factory standard grey plastic one but this carbon skeg has features that the Valley skeg does not.

The blade is foil shaped like the wing of an aircraft with the leading edge thicker than the back of the blade. This shape minimizes turbulence and promotes an easy flow of water over the blade when the skeg is deployed. Less turbulence equals to less drag that leads to less effort and possibly more speed.

While speed has never been my goal, less effort is certainly welcome.

The skeg blade is a real work of art and the finish is incredible.

Somehow I felt that such a beautiful accessory looked out of place on the basic finish of the Nordkapp LV's skeg box but I was keen to find out if the blade would actually fit and how much effort the retrofit required. After all the existing skeg blade was still working fine...

I inserted a 2.5mm Allen key (like the one you get with IKEA furniture, but smaller) into the skeg's control knob found next to the cockpit and tried to undo the grub screw. Initially it would not budge but a squirt of water dispersant (WD40) and a few minutes later the key turned and the pinch on the skeg cable was released.

salt built up under the skeg control knob,washes away easily...

The knob was free and now I could pull out the skeg blade past its normal maximum deployed setting; the wire came out easily.

factory VCP skeg blade removal

Norbert supplied me with the stainless steel wire that I had to cut as each kayak model has a slightly different wire length .

The carbon skeg has a very neat grub screw that pinches the cable that is inserted into blade (not show here). I measured the length of my existing Valley skeg wire and cut the new one to length with a pair of diagonal cutters (a decent pair of plier would have done the same job).

I fastened the grub screw on the carbon blade onto the wire, inserted the blade into the skeg box and easily wiggled the wire back into the housing all the way to the control knob. The skeg blade was sitting flush with the hull, all the way in the skeg box, before I aligned the knob over the hole in "slider tube" and secured it tightly with the Allen key. I made sure that the knob was in the "retracted" position or I would not be able to deploy that skeg all the way like before.

Norbert's skeg blade sits in the skeg box without any wiggle and the two little rubber washers on the pivot point offer just enough resistance to keep the blade in position preventing the skeg blade from creeping back up when the kayak is at speed (one of my kayaks does that and I am yet to fix it...).

But how does the skeg perform in the field, err water?

It seems to have a crisper feel with the lowering amount precisely translating to directional changes. There are no wobbles and no "skeg hum" as I have in some of my other kayaks when I speed down the face of a wave.

As for increased speed?

I can't attest to that as I don't have a GPS to measure precisely the speed of the kayak.

All I really want is to have the kayak on the beach, belly up, with the skeg standing up proud showing off that sexy carbon weave :-)

Norbert Gancarz can be contacted at norbertga@o2.pl

.

What a great looking skeg!

ReplyDeleteManufacturing new skegs to existing skeg boxes can be tricky.

I’m sure Norbert already looked in to it, because it’s important that the skeg has a built in breaking point (e.g. materials void) in order to snap before the box snaps.

Skeg boxes can crack (and flood the aft compartment) only because the skeg was deployed while landing/ or during a side broach.

Norbert's carbon skeg now reviewed also by Douglas Wilcox at http://seakayakphoto.blogspot.com.au/2013/06/carbon-fibre-sea-kayak-skeg-review-and.html

ReplyDelete